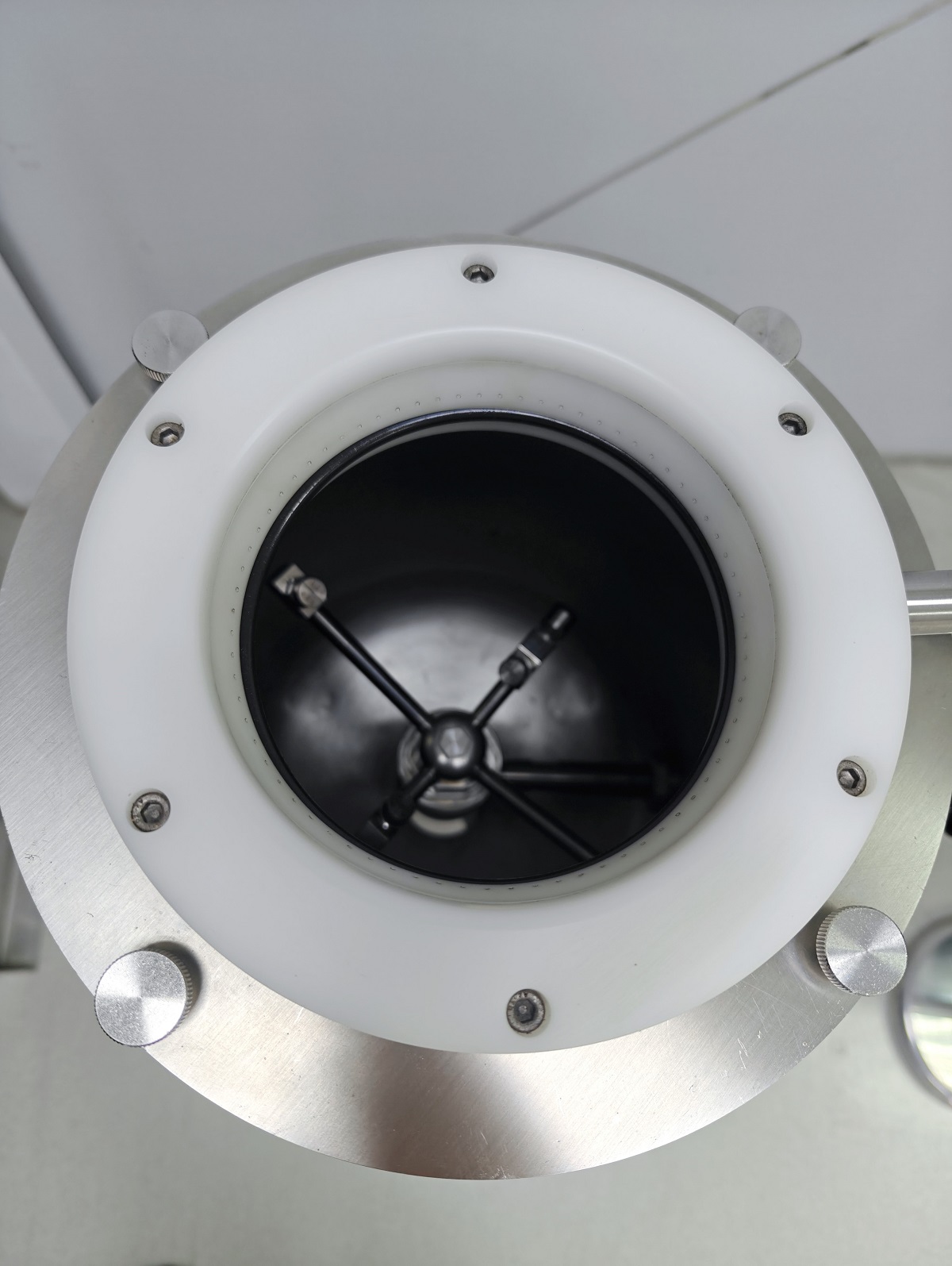

360 ° flushing nozzle

Rotating impeller design, 360 air solvent alternating flushing nozzle. Sealed adapters prevent solvent leakage.

Quick disassembly structure, easy to clean

Quick screw design. It can quickly clean the inside of the barrel, with a polished stainless steel barrel body and open discharge.

Safety explosion-proof

The whole machine adopts pneumatic design, and the impeller adopts mechanical ceramic bearings. Stainless steel pneumatic valves are used for fluid and air switching. After the equipment is grounded, safe and explosion-proof operation can be achieved.

Small size, easy to deploy

The barrel body with a diameter of 250 occupies a small space, and the standardized discharge interface is easy to recycle waste liquid.

Application scenarios:

Furniture, ceramic bathroom, 3C electronics, automotive parts, hardware and plastic.

|

Maximum paint pressure (low-pressure system) |

300 psi(21 bar,2.1 MPa) |

|

Maximum air pressure |

100 psi(7 bar,0.7 MPa) |

|

Solvent inlet size |

(φ6*8) |

|

Air inlet size |

(φ6*8) |

|

Valve controls the size of the air pipe |

(φ4*2.5) |

|

Operation temperature |

5 - 50°C(41 - 122°F) |

|

Size |

φ250mm*H620mm |

|

Applicable fluids |

Single component, solvent based and water-based coatings, polyurethane, epoxy resin, etc |

|

Immersion components |

316 stainless steel, 304 stainless steel,FFKM、PTFE |

|

Maximum solvent consumption |

150cc |

|

Weight |

About 10Kg |