Made of all 316 stainless steel material, electrolytic polished, with the valve needle parallel to the fluid channel for quick cleaning and color change.

The switch seat is made of FFKM material, which has high reliability, high closure with the valve seat needle, and long service life.

Valve seat reflux design allows paint to circulate at the color changing valve, reducing paint sedimentation.

Valve precision machining, with a service life of over 1 million (depending on the characteristics of different coatings).

The applicable coatings are diverse, with a wide range of applications, quick disassembly, and easy increase or decrease in quantity.

Flow channel through design, smooth without dead corners, joint without raw material tape, universal stainless steel fluid joint.

Application scenarios:

Furniture, ceramic bathroom, 3C electronics, automotive parts, hardware and plastic.

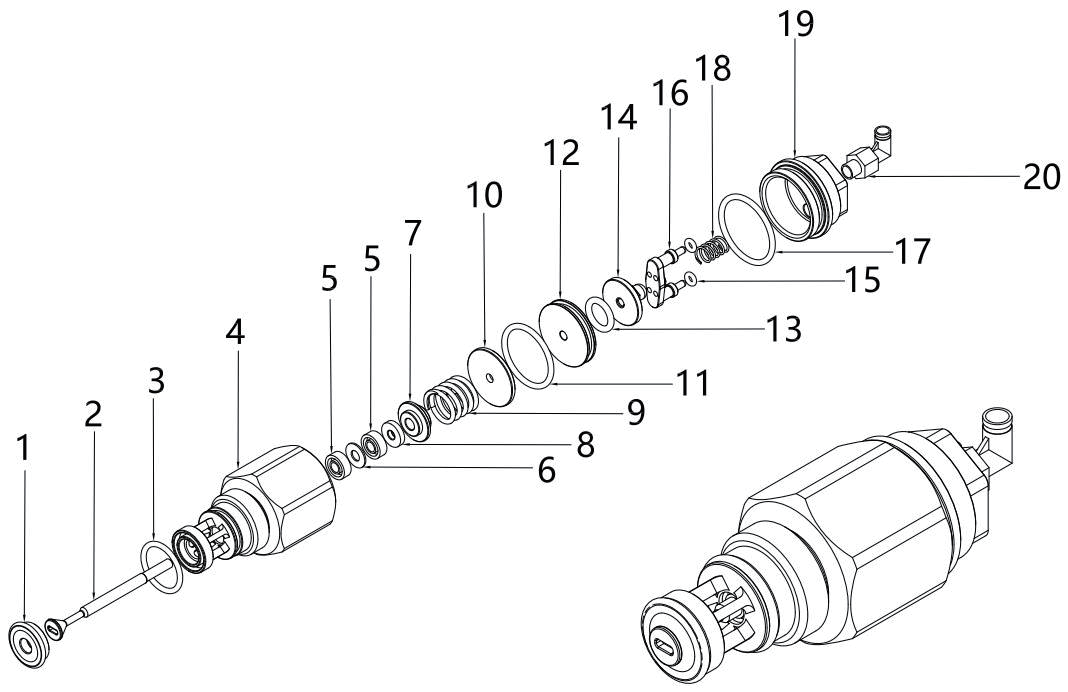

Explosion view of single valve

Hose connector

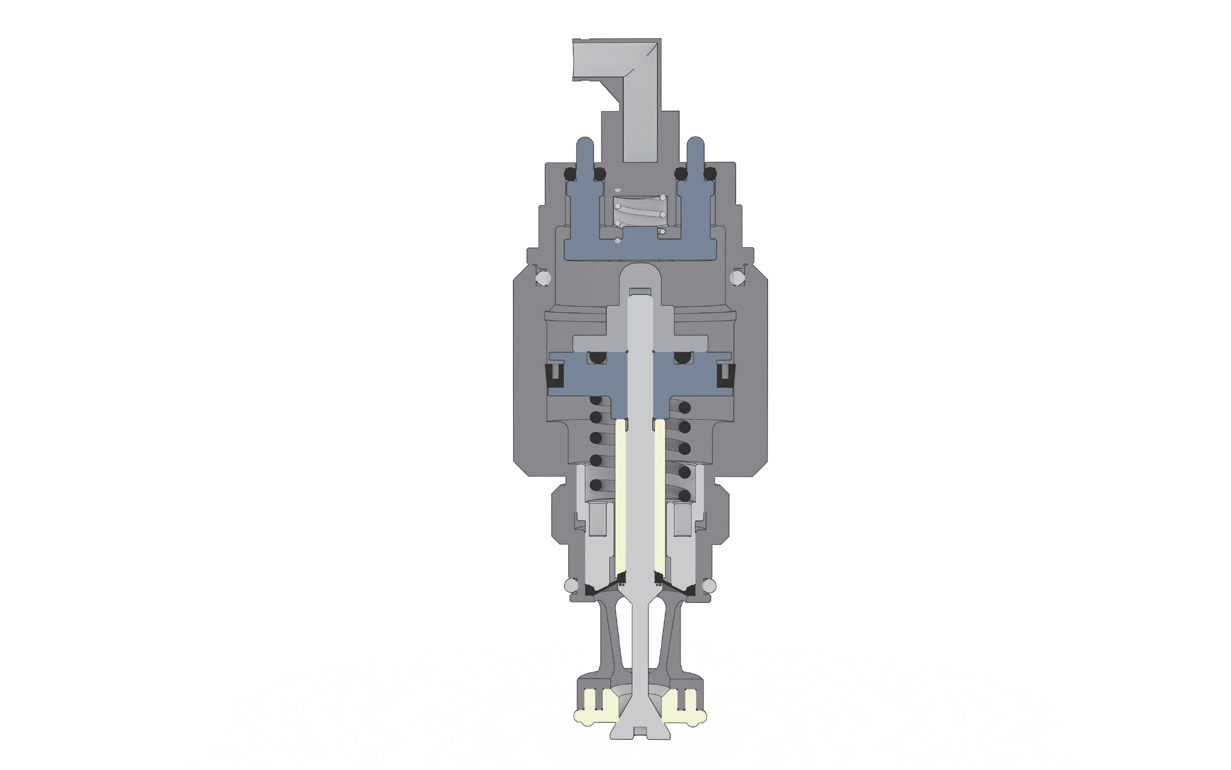

Diaphragm type

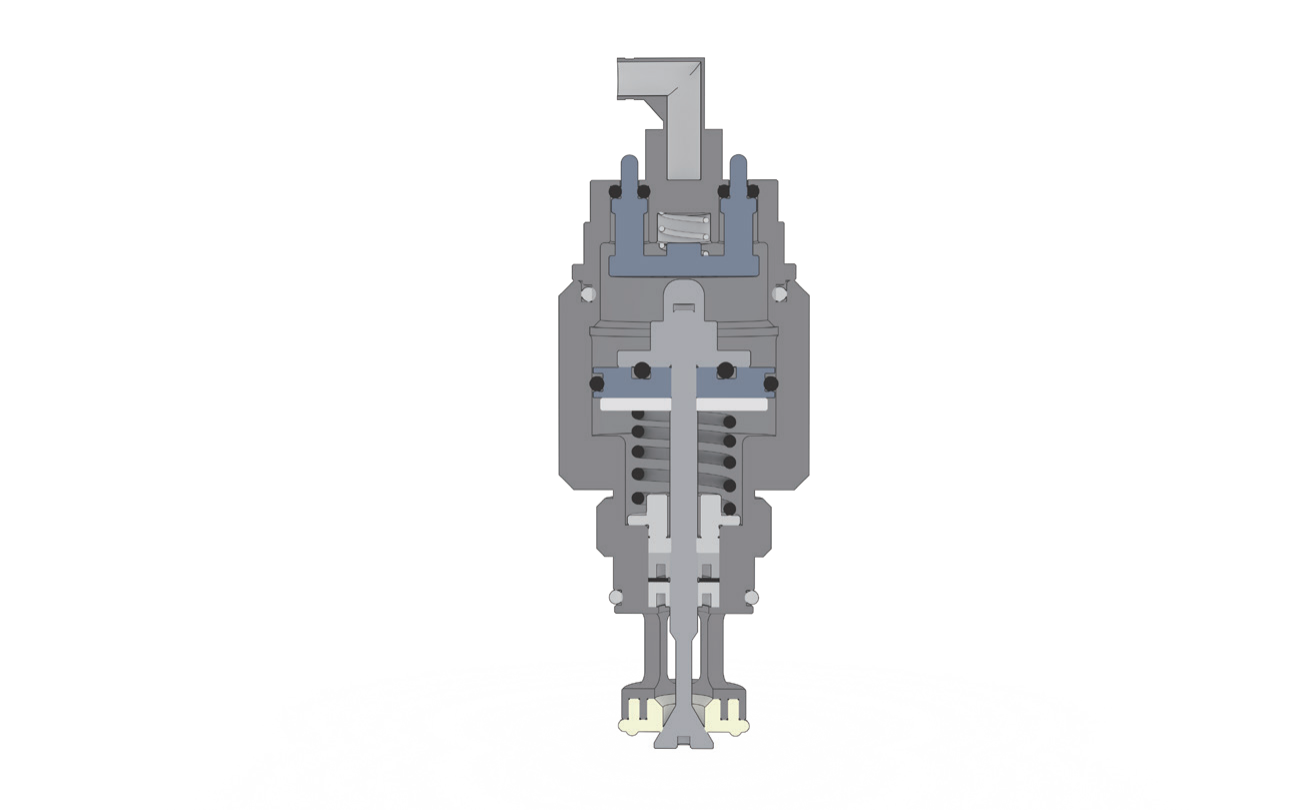

Shaft seal type

|

Maximum paint pressure |

300 psi(21 bar,2.1 MPa) |

|

Maximum air pressure |

100 psi(7 bar,0.7 MPa) |

|

Fluid inlet size |

1/4 G (f) (optional hose connector) |

|

Fluid outlet size |

1/4 G (f) (optional hose connector) |

|

Fluid reflux size |

1/4 G (f) (optional hose connector) |

|

Air inlet size |

4mm*2.5mm |

|

operation temperature |

5 - 50°C(41 - 122°F) |

|

Applicable fluids |

Primer, topcoat, clear coat, solvent and water-based coatings, polyurethane, epoxy resin, etc |

|

Immersion components |

316 stainless steel, FFKM, uhmwpe |