Powerful self-developed spraying software

After years of market refinement, spray painting software has become very mature, intelligent, convenient, and fast response can achieve high-quality and high-precision spray painting control.

Safe and explosion-proof, safe and reliable

Different robots can have built-in motors, external explosion-proof servos, and explosion-proof pressure sensors.

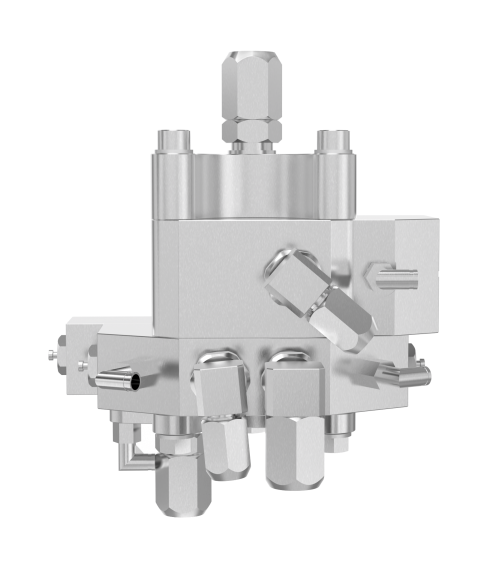

Space saving, lightweight

The color changing module is small in size and light in weight, easy to integrate, and convenient for increasing or decreasing the quantity.

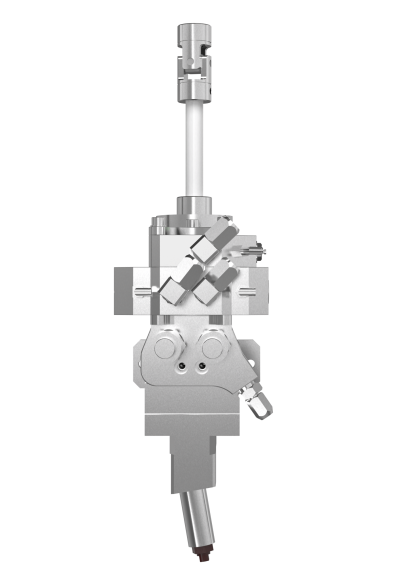

Integrated atomizer process control, explosion-proof design, safe and convenient

The atomizer process control box can be installed in the spray room, including a color changing valve, atomizer switch gun, and automatic control of fan-shaped atomization.

Application scenarios

Furniture, ceramic bathroom, 3C electronics, automotive parts, hardware and plastic

|

Maximum paint pressure |

300 psi(21 bar,2.1 MPa) |

|

Maximum air pressure |

145psi(10bar,1.0 MPa) |

|

Proportion range |

1: 1 to 30: 1, ±2% |

|

Flow range |

1KG: 10-1000ml/min;2KG: 20-1200ml/min±2% |

|

Repeatability |

20 - 5000 cps |

|

Paint viscosity range noise |

<75 db(A) |

|

Operation temperature |

5 - 50°C(41 - 122°F) |

|

Applicable fluids |

Single component or multi-component, solvent based and water-based coatings, polyurethane, epoxy resin, acid catalyzed varnish, etc |

|

Immersion components |

Stainless steel, composite materials PFPE、PTFE |