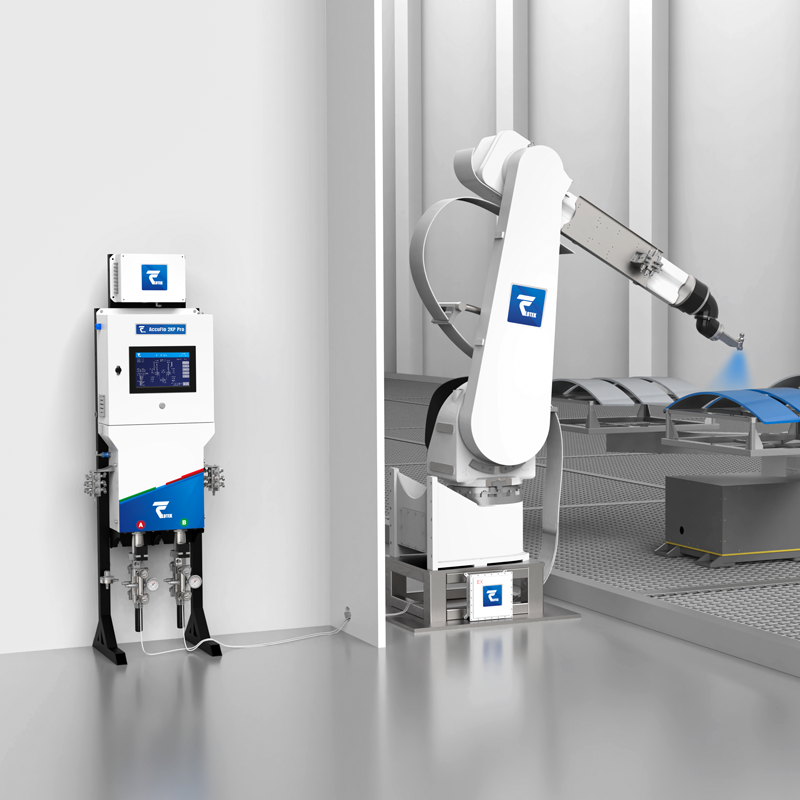

Why choose Accuflo 2 KP

Accuflo 2 KP has the following advantages:

◆It can save up to 80% of solvent waste and mixed paint waste.

Reduce the cost of handling hazardous chemical waste.

◆Shorten color change time and improve system maneuverability.

◆Maintain optimal spraying effect through built-in fluid pressure control and save users considerable paint.

The product components are durable and reliable, and easy to maintain.

Dual component remote mixing valve group

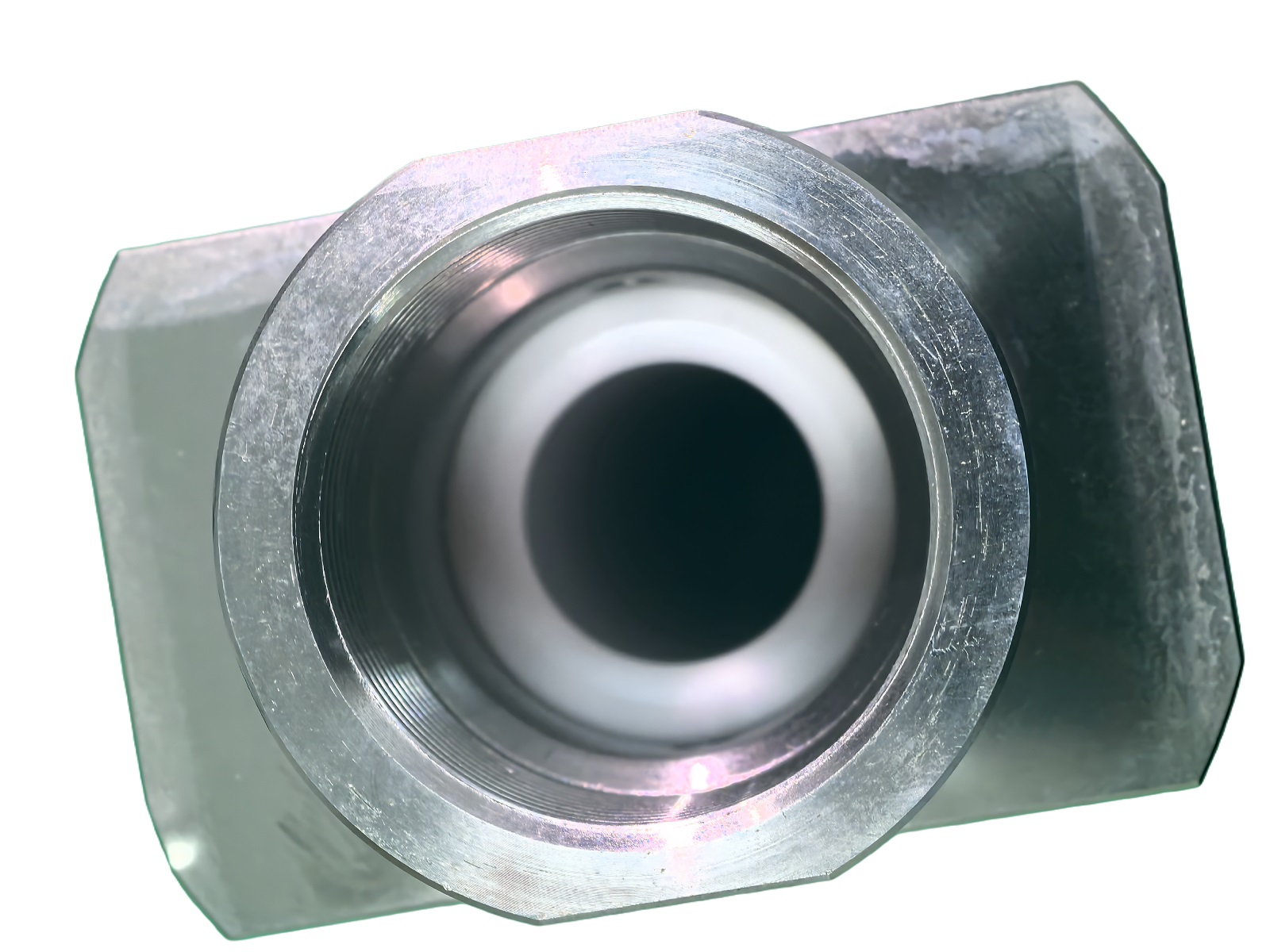

Throat piston spare parts kit

Ceramic cylinder body

Application scenarios:

Furniture, ceramic bathroom, 3C electronics, automotive parts, hardware and plastic

|

Maximum paint pressure (low-pressure system) |

300 psi(21 bar,2.1 MPa) |

|

Maximum paint pressure (high-pressure system) |

1500 psi(105 bar,10.5 MPa) |

|

Maximum air pressure |

100 psi(7 bar,0.7 MPa) |

|

Proportion range |

0.1:1 to 100:1, ±1% |

|

Flow range |

20-800 ml/min |

|

Repeatability |

±1 % |

|

Paint viscosity range |

20 - 5000 cps |

|

Noise |

<75 db(A) |

|

Power supply |

AC 220 V , 50-60 Hz , 4 A |

|

Operation temperature |

5 - 50°C(41 - 122°F) |

|

Wall mounted split type |

520mm ×560mm×2000mm (reference) |

|

Applicable fluids |

Single component or multi-component, solvent based and water-based coatings, polyurethane, epoxy resin, acid catalyzed varnish, etc |

|

Immersion components |

316 stainless steel, ceramics and composite materials FFKM、PTFE |