Compared to traditional systems, Accuflo 1kp has achieved savings in multiple aspects.

Compared to the most efficient traditional proportioning system, it can reduce up to 80% of flushing waste.

Save material mixing amount - very suitable for materials with short curing time.

Quick

color change speed and less waste from washing, thus avoiding waste and

shortening downtime waiting time.

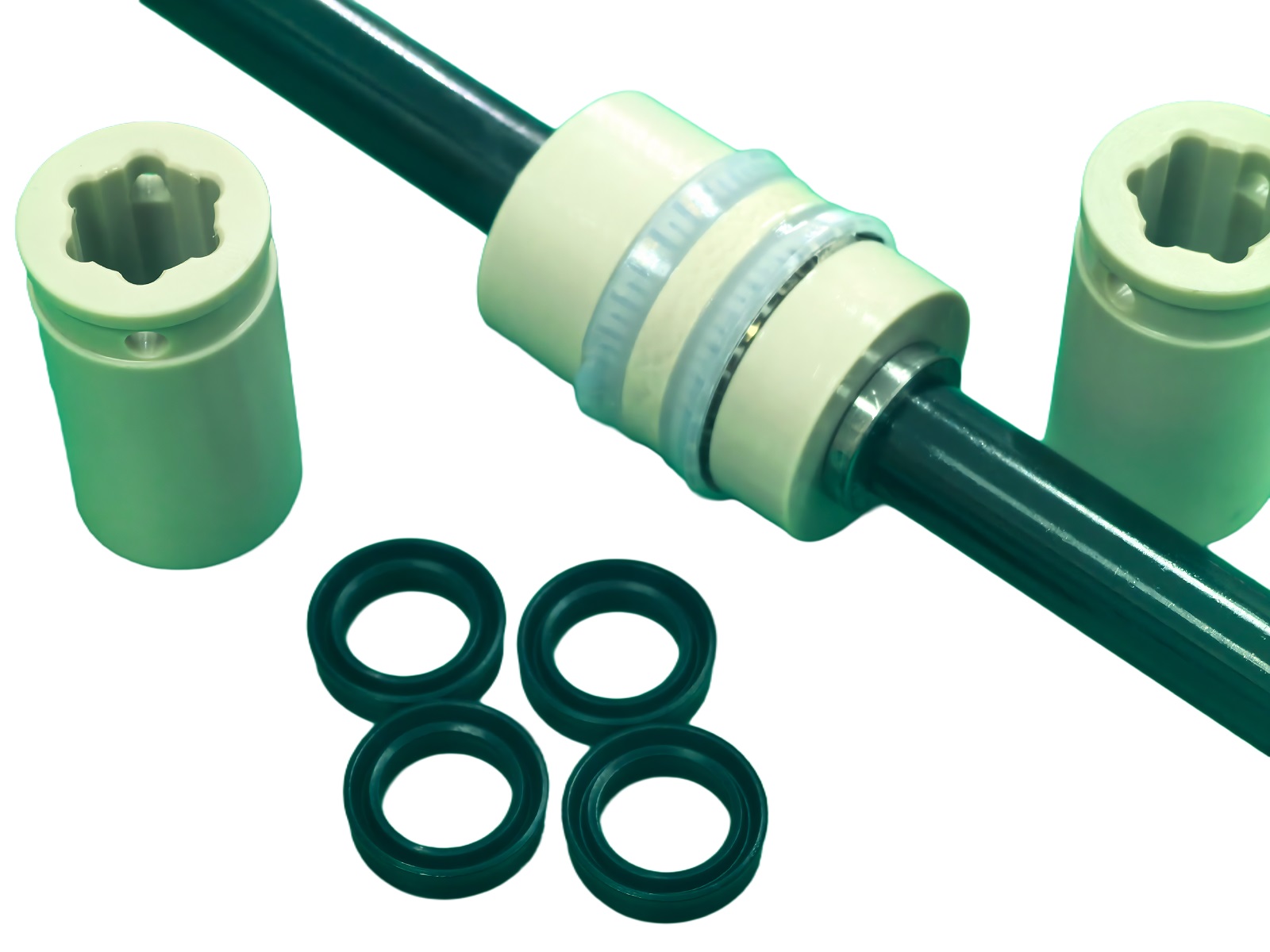

Throat piston spare parts kit

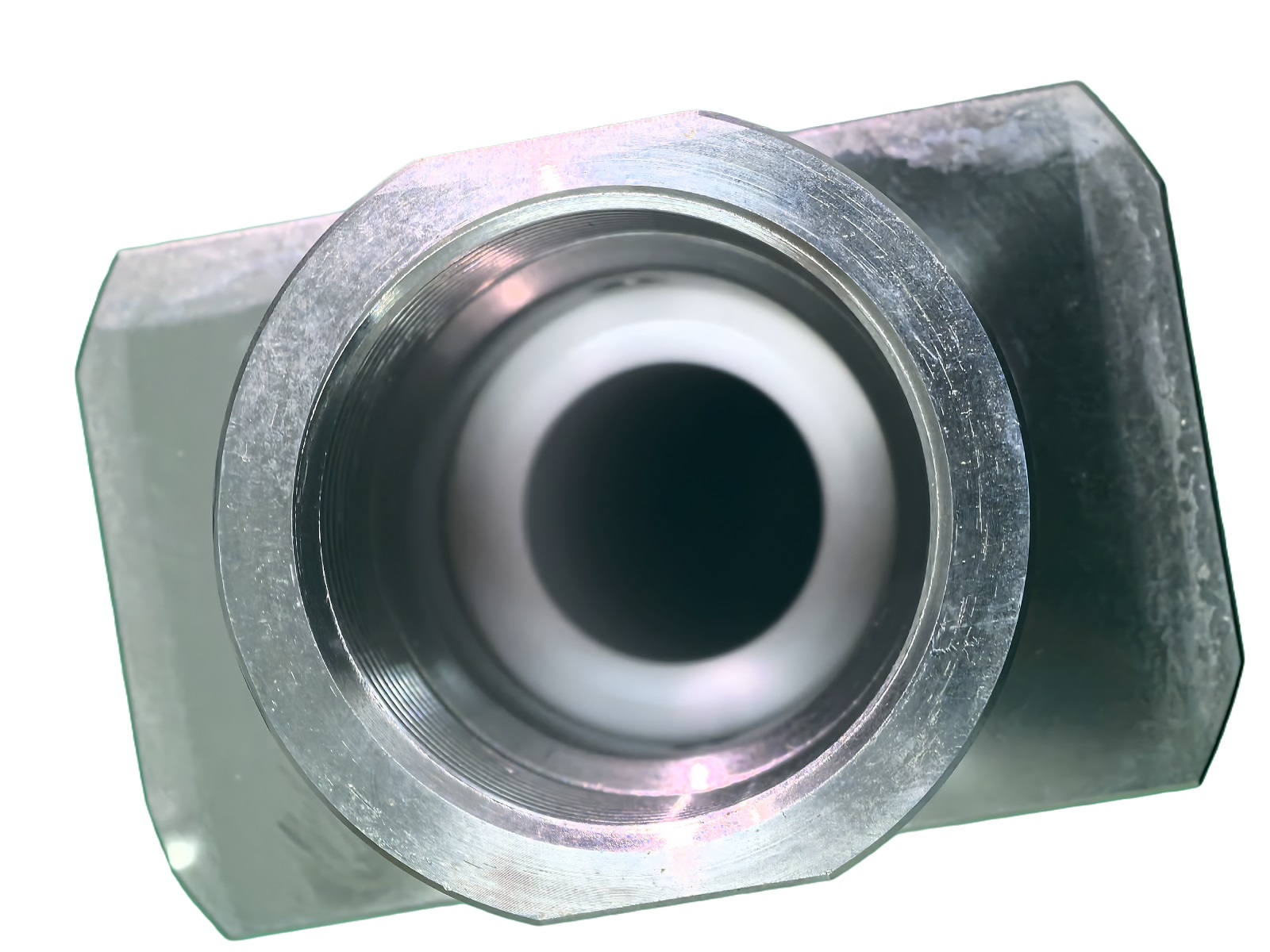

Ceramic cylinder body

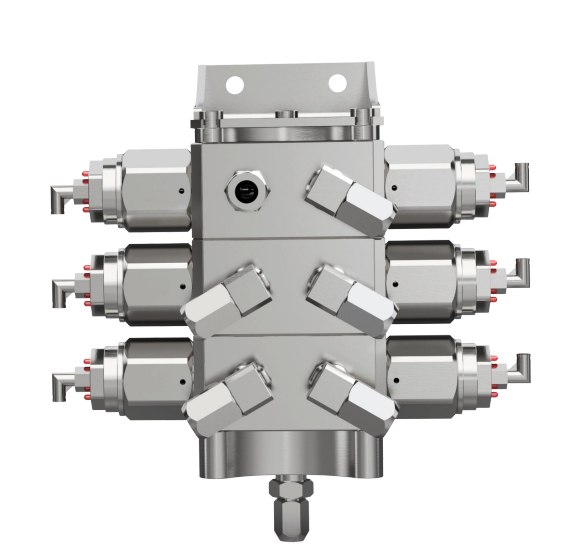

CV300

low pressure color changing valve group

Application scenarios:

Furniture, ceramic bathroom, 3C electronics, automotive parts, hardware and plastic

|

Maximum paint pressure (low-pressure system) |

300 psi(21 bar,2.1 MPa) |

|

Maximum paint pressure (high-pressure system) |

1500 psi(105 bar,10.5 MPa) |

|

Maximum air pressure |

100 psi(7 bar,0.7 MPa) |

|

Minimum flow rate |

≤5cc/min |

|

Flow range |

5-700 cc/min |

|

Repeatability |

±1 % |

|

Paint viscosity range |

20 - 5000 cps |

|

Noise |

<75 db(A) |

|

Power supply |

AC 220 V , 50-60 Hz , 4 A |

|

Operation temperature |

5 - 50°C(41 - 122°F) |

|

Wall mounted split type |

520mm×560mm×2000mm (reference) |

|

Applicable fluids |

Single component, solvent based and water-based coatings, polyurethane, epoxy resin, acid catalyzed varnish, etc |

|

Immersion components |

316 stainless steel, ceramics and composite materials FFKM、PTFE |